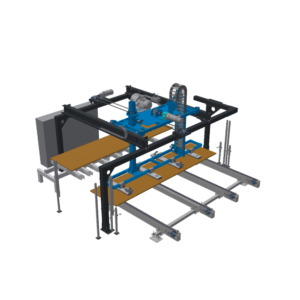

ProLogScanner®

Primary and Secondary Breakdown Scanners

The ProLogScanner is a linear scanner, equipped with 3 to 4 sensors. Each sensor can be equipped with 2 cameras for a total of 6 to 8 cameras per scanner to read a “3D” or a “TrueShape” profile for log or cant. Each sensor’s components are factory calibrated, providing a fast and efficient way to change sensors when needed. No more laser and camera alignments. Fast, easy and user-friendly calibration. The log or cant model generated is then sent to an optimizer software program to apply the best cutting pattern solution based on a predefined set of parameters.

ProLogTurner®

Primary Breakdown Scanners

The ProLogTurner is a linear scanner, equipped with 3 to 4 sensors. Each sensor can be equipped with 2 cameras for a total of up to 8 cameras per scanner to read a “3D” profile for logs. Each sensor’s components are factory calibrated, providing a fast and efficient way to change sensors when needed. No more laser and camera alignments. Fast, easy and user-friendly calibration.

With advanced algorithms, the logs are oriented to the optimal position before being processed.

Take Your Lumber Production to the Next Level

Start Your Initial Project Consultation Today

Don’t miss this opportunity to revolutionize your lumber production. PLCUSA Network is here to streamline operations, optimize output, and maximize profits. Here’s what you stand to gain from our free consultation:

- EXPERT ADVICE: Get insights from industry experts who understand the ins and outs of lumber production automation.

- CUSTOMIZED SOLUTIONS: Our team will work to identify automation solutions tailored to the specific needs of your sawmills, planer mills, grading equipment, and more.

- INCREASED EFFICIENCY: Discover how to make your lumber production faster and more cost-effective with our optimization strategies.

Take the next step to a more profitable future. Fill out the form now for your Initial Project Consultation.

Why you should trust PLCUSA with a Free “Initial Project Consultation.”

- 119 years of team experience

- Grade “A” member of ISNetworld

- Ongoing support

Reviews

There are no reviews yet.